RTEX在全自动铝条折弯机上的应用

时间:2024-03-21 来源:http://www.jncsjx.com/ 发布人:昌盛机械

铝条折弯机的设备组成:

Equipment composition of aluminum bar bending machine:

该设备本体由机身机架铝框背板自动接料装置步进给料机构折弯机构自动断料机构电气控制系统动力控制系统控制箱及触摸屏人机界面等结构组成。

The device body is composed of an automatic material receiving device for the aluminum frame backplate of the body frame, a step feeding mechanism, a bending mechanism, an automatic material cutting mechanism, an electrical control system, a power control system, a control box, and a touch screen human-machine interface.

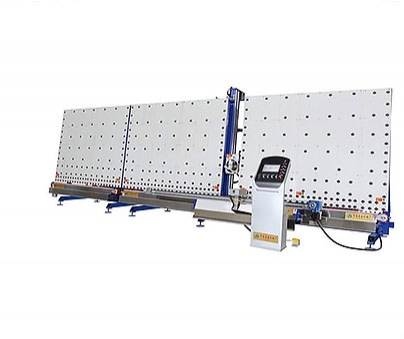

铝条全自动折弯机设备组成图

Composition diagram of aluminum bar fully automatic bending machine equipment

自动接料装置:

Automatic feeding device:

由接头定位部件和铝条定位部件组成,当铝条尾部到达信号发出时,接料系统会自动定位铝条尾部,等待下一条铝条的自动续接。

Composed of joint positioning components and aluminum strip positioning components, when the signal is sent at the tail of the aluminum strip, the feeding system will automatically position the tail of the aluminum strip and wait for the automatic continuation of the next aluminum strip.

步进给料机构:当控制系统发出步进长度信号时,由该系统执行给料。

Step feeding mechanism: When the control system sends a step length signal, the system executes feeding.

折弯机构:折弯机构的折弯角度可以精确调节和控制。

Bending mechanism: The bending angle of the bending mechanism can be precisely adjusted and controlled.

自动断料机构:

Automatic material cutting mechanism:

当初始上料或一个框折弯完成时,断料机构会自动切断铝条。

When the initial feeding or bending of a frame is completed, the cutting mechanism will automatically cut the aluminum strip.

自动断料机构:

Automatic material cutting mechanism:

当初始上料或一个框折弯完成时,断料机构会自动切断铝条。

When the initial feeding or bending of a frame is completed, the cutting mechanism will automatically cut the aluminum strip.

电气控制系统:

Electrical control system:

电气控制系统是整个设备的核心部分,设备的控制软件安装在MC运动控制器中。所有的控制指令运算工作输入输出信号系统状态监视,以及与操作人员的信息交流均由该部分完成。

The electrical control system is the core part of the entire equipment, and the control software of the equipment is installed in the MC motion controller. All control instruction calculations, input and output signal system status monitoring, as well as information exchange with operators, are completed by this section.

该系统采用松下支持RTEX总线的A6N伺服及电机。RTEX具有极高的性价比,采用RTEX总线控制系统后,客户在不增加电机成本的情况下,大幅降低了配线安装工作。100M的网络带宽和RTEX优异的稳定特性,确保了MC1002R与系统各个A6N伺服驱动器之间的控制周期能够达到0.5ms,从而大幅提高了客户机器的控制精度。

The system adopts Panasonic's A6N servo and motor that support RTEX bus. RTEX has a very high cost performance ratio. By adopting the RTEX bus control system, customers can significantly reduce wiring and installation work without increasing motor costs. The 100M network bandwidth and excellent stability characteristics of RTEX ensure that the control cycle between MC1002R and various A6N servo drivers in the system can reach 0.5ms, greatly improving the control accuracy of the customer's machine.

动力控制系统:

Power control system:

由数个气动电磁阀相应气路众多气动元件,以及控制信号回路组成气动动力系统,负责完成设备复杂的程控动作。

The pneumatic power system is composed of several pneumatic solenoid valves, corresponding pneumatic circuits, numerous pneumatic components, and control signal circuits, responsible for completing complex programmable actions of the equipment.

触摸屏软件界面:

Touch screen software interface:

操作人员对设备的使用所需要的大量的数据输入,以及操作人员需要了解的设备运行的信息,均通过触摸屏来完成。

The large amount of data input required for the use of equipment by operators, as well as the information about the operation of the equipment that operators need to know, are all completed through the touch screen.

铝条折弯的工艺流程

The process flow of aluminum bar bending

设备上电后,通过触摸屏输入铝框图形参数,踩下脚踏开关设备开始运行,控制系统通过判断原料位置选择自动上料流程还是直接进入自动折弯流程,并自动判断当前原料的余料接头位置是否出现在禁折区。步进给料系统将由控制系统计算后的料长精确的给进至折弯刀头,由折弯系统完成需要的折弯形状。

After the device is powered on, input the aluminum frame graphic parameters through the touch screen, press the foot switch, and the device starts running. The control system selects the automatic feeding process or directly enters the automatic bending process by judging the position of the raw materials, and automatically determines whether the position of the remaining material joints of the current raw materials is outside the prohibited folding area. The step feed material system will accurately feed the material length calculated by the control system to the bending blade, and the bending system will complete the required bending shape.

重复以上两步,直至完成整个铝框成形流程。

Repeat the above two steps until the entire aluminum frame forming process is completed.

在铝框折弯过程中,随时会出现当前加工的铝条即将用完的情况,通过系统自动判断可使后续铝条自动续接至当前铝条尾部,不中断当前铝条的成形工作。

During the bending process of the aluminum frame, there may be situations where the current processed aluminum bars are about to be used up. The system automatically determines that the subsequent aluminum bars can be automatically connected to the tail of the current aluminum bar without interrupting the forming work of the current aluminum bar.

控制方案

Control plan

控制器选用和利时MC1002R,是专用于运动控制的可编程控制器,一般用作单台复杂运动机械设备的控制核心。MC1002R支持RTEX总线控制系统,可以连接多达32轴的松下A6N伺服。

The controller selected is the Helishi MC1002R, which is a programmable controller specifically designed for motion control and is generally used as the control core for a single complex motion mechanical equipment. MC1002R supports RTEX bus control system and can connect up to 32 Panasonic A6N servos.

MC具有高精度64位运动解算,双核ARM Cortex-A9 CPU,667M主频控制器采用ARM Cortex-A9 CPU667M主频;运算采用64位双精度浮点数进行运算,确保运算精度。

MC has high-precision 64 bit motion calculation, dual core ARM Cortex-A9 CPU, and 667M main frequency controller using ARM Cortex-A9 CPU667M main frequency; The operation uses 64 bit double precision floating-point numbers to ensure accuracy.

MC1002R运动控制器

MC1002R motion controller

设备由触摸屏MC运动控制器和伺服系统组合成一个开放式运动控制系统,根据折弯工艺要求由MC运动控制器对各个输出点伺服单元进行控制,送料伺服单元收到命令后驱动伺服电机进行送料,实现铝条折弯机的运动控制和逻辑控制。控制流程如右图

The device is composed of a touch screen MC motion controller and a servo system to form an open motion control system. According to the bending process requirements, the MC motion controller controls the servo units at each output point. After receiving the command, the feeding servo unit drives the servo motor to feed, realizing the motion control and logic control of the aluminum bar bending machine. The control process is shown in the figure on the right

- 全自动丁基胶涂布机操作规程 2024/12/14

- 丁基胶涂布机在使用的常见问题 2024/12/13

- 双组份打胶机如何调整滴胶量? 2024/12/09

- 中空玻璃生产线的磨损如何解决 2024/12/07

- 双组份打胶机对于打胶工作完成很重要 2024/12/05

- 全自动封胶线的工业自动化设备介绍 2024/12/03

- 玻璃涂布机设备:设备存在的安全隐患 2024/11/25

- 中空玻璃加工设备:玻璃开胶的应急处理措施 2024/11/21

- 中空玻璃生产线:玻璃起雾怎么办?昌盛为您解决! 2024/11/20

- 中空玻璃加工设备:选择中空玻璃,创更舒适的环境 2024/11/18

当前位置:

当前位置:

产品分类Product categories

产品分类Product categories

联系我们Contact us

联系我们Contact us